– Now that your parts are printed how do you separate them from the base plate?

Manufacturing technology is changing at such a rapid pace that it’s hard to imagine what’s coming next or better yet, what’s already here and growing at a rapid pace.

Now we have 3D printed parts and components varying in shape, size, and material composition. One thing they all have in common is the need to be removed or separated from the base plate they are printed on. Band sawing is one of the two options. The other is EDM wire cutting which can be a very slow and costly process when separating these pieces.

Several band saw machine manufacturers already produce machines specifically designed for the 3D printed parts with the advanced plate holding systems and tighter tolerances allowing for better accuracy in both straightness and surface finish requirements. A precise cut is a must to maintain minimal material loss and dimensional accuracy of the parts.

WIKUS recently found solutions and cost savings for several applications cutting various 3D printed materials such as Inconel 718 with hardness values of 43 HRC using both our DUROSET® and FUTURA® carbide products.

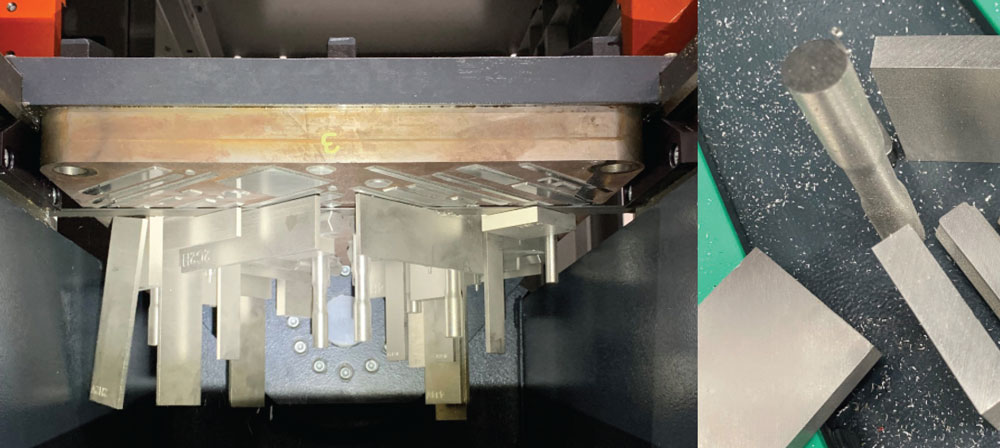

In one case the Level 2 DUROSET® 2.5/3.4 TPI was the go-to blade when cutting parts supported by very small bristle like columns attached to the base plate. Blade life was of higher importance here as opposed to surface finish due to the additional machining requirements already established for the parts. The rugged, set and ground geometry of the DUROSET® was a benefit when subject to the small, fragmented chips being created and dragged back through the cut. (As shown in the picture 1).

In another case, finish and accuracy were both critical. The current method being used for this application was EDM with cut times of up to 5 hours and hundreds of dollars for the wire consumed to make the cut.

Our choice to use FUTURA® was an easy one given the performance, accuracy and finish needed. Quite different from the previous application the 3D parts in this scenario were solid to the base with a solid build area on each individual part. (As shown in the picture)

Any deflection could ruin the parts or base plate and a rough surface finish would require additional machining. The tooth geometry of FUTURA® is one that shares the chip load among several teeth to produce 7 chips, thus resulting in a very smooth surface finish. In this application we were able to reduce the cutting time of 5 hours using the EDM method to just under 3 hours using the Level 3 FUTURA® 3-4 TPI.