Delivering the right solution based on your customer’s needs

Choosing the correct blade to satisfy a range of cutting requirements and applications is critical. Whether you’re dealing with a small fab shop, a steel distribution center, a forging producer or a primary steel producer each has its own unique requirements and expectations.

Performance, blade life and cost are all considerations when determining which band saw blade is right for your specific application. The goal is to obtain the lowest cost per cut, while maintaining an acceptable surface finish and find the optimal solution for ensuring continued output and profitability.

- Understand what you are trying to achieve

- Understand your product and its features

Each blade has individual design and functionality characteristics. - Understand Blade Impact

When cutting large, continuous areas of solid material, the stresses on the teeth after initial impact tend to be consistent in terms of intensity and direction. The teeth proceed all the way through the cut, maintaining contact with the metal. Since no additional impact shocks occur after initial contact, there is no excessive stress on the teeth as they cut through the material. The blade’s longevity and ongoing performance in this type of application are based on the blade’s wear resistance, which is largely dependent on its tooth geometry and composition.

When cutting structural steels or bundles, the band saw blades teeth are subjected to multiple forces from different directions. Shifting material, blade pinching and vibration increase the risk of tooth strippage. Tooth geometry can play a big role in finding the solution. - Determine What Materials You Are Cutting

• Type

• Size

• Condition - Look at the Blade Characteristics

The best blade is not necessarily the most expensive or the least expensive, rather the one that has been carefully selected to cut quickly, efficiently, and economically. A blade must have the following characteristics in order to produce good-quality parts economically:

• Hardness: high heat resistance

• Toughness: shock resistance to prevent chipping or fractures.

• Wear resistance: for blade longevity - Selecting Blade Properties

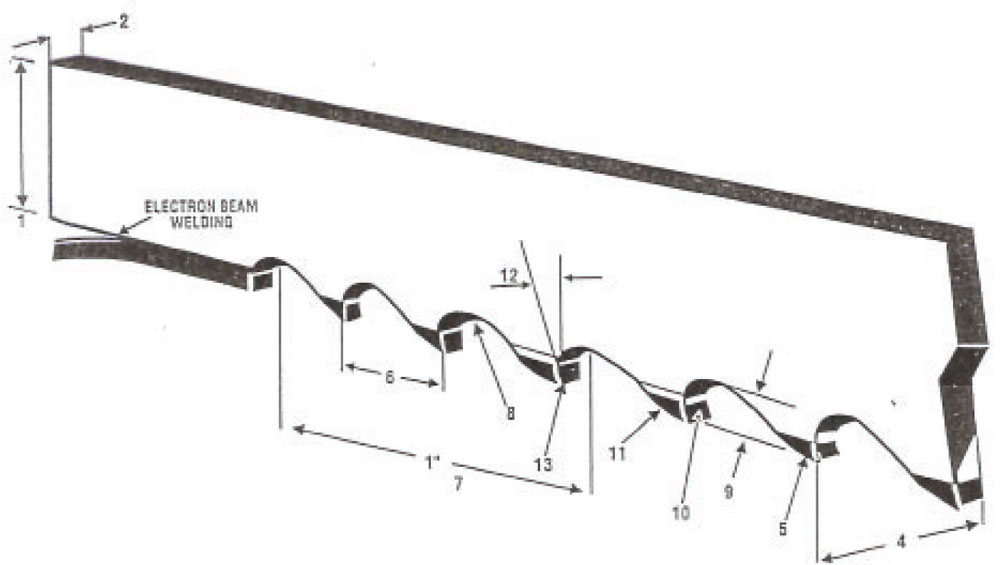

The blade’s properties are chosen based on the type of cutting that is being performed. Blade width, length, thickness, rake angle, tooth pitch, tooth tip composition - Be Aware of the Other Variables

• Equipment Condition

• Coolant flow and ratio

• Operator Skill.

Ability to observe the cut to ensure the decent rate is correct

Ability to make adjustments regarding feed and speed for various materials

Ability to read the chips to determine if the blade and equipment are cutting properly

Ability to identify equipment problems and correct