By Rich Licht, WIKUS RSM

As a new Regional Sales Manager with WIKUS Saw Technology, I was quickly getting acclimated and adjusted to the technical demands of the position. The WIKUS bandsaw blade product line is specifically designed to provide increased productivity with long-term, cost saving solutions. So, having the ability to properly analyze, communicate and demonstrate our value-added products and services, is critically important for not only my success, but also the success of both our distributors and consumers.

After 6 full months on the job, I was finally getting my first real opportunity with a large, high-production sawing facility. We made our initial contact with George Ott (Plant Manager) and Mike Stiles (Director of Purchasing) from Rockland Manufacturing, in Bedford, PA through our distribution partner, Hercules Sealing Products. After introductions were made, George and Mike took us for a tour of the facility and to one of their biggest sawing challenges, cutting hardened induction chrome piston cylinders.

The machine they were using was a HEM saw, model H 105-A. At this present time, they were using a competitor’s blades and were complaining that they were consistently having issues with uneven cuts and poor blade life. After researching various manufacturer’s, Rockland specifically requested WIKUS to meet with them and to see if we had any potential solutions. After gathering the critical data and truly understanding the needs of their cutting demands, I gathered with our technical team to discuss some product options, along with the proper operating procedures in order to maximize our performance.

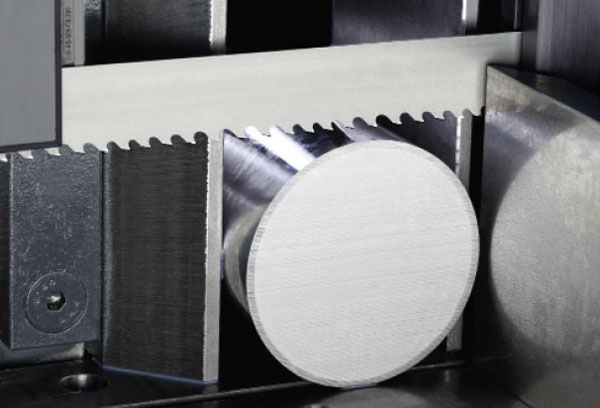

Once we finalized our strategy, we then set up a specific date to test, which would allow us to gain the important data required to find Rockland their very best sawing solution. Based on their current sawing equipment, the material they were cutting and the results they desired, we decided to go with our WIKUS FUTURA SN, carbide-tipped blade. As a group, we focused on 3 important facets of their needs when conducting this specific test, 1) even, flush cuts; 2) increased number of cuts per blade and 3) overall, longer blade life.

Once we finalized our strategy, we then set up a specific date to test, which would allow us to gain the important data required to find Rockland their very best sawing solution. Based on their current sawing equipment, the material they were cutting and the results they desired, we decided to go with our WIKUS FUTURA SN, carbide-tipped blade. As a group, we focused on 3 important facets of their needs when conducting this specific test, 1) even, flush cuts; 2) increased number of cuts per blade and 3) overall, longer blade life.

We conducted the test over 2 full days. The first day was recording data of their current sawing operations, with the incumbent’s blade. We were paying specific attention to their operating parameters (feeds and speeds), as it was important to know how the operator was trained and where we could potentially help to improve their overall performance.

We conducted the test over 2 full days. The first day was recording data of their current sawing operations, with the incumbent’s blade. We were paying specific attention to their operating parameters (feeds and speeds), as it was important to know how the operator was trained and where we could potentially help to improve their overall performance.

On the 2nd day, we put on the WIKUS FUTURA® SN and programed the saw to our preferred, operational settings (feeds and speeds). At the beginning, we first conducted our standard break-in cut to allow the tooth pattern to smooth out and enhance the removal rates. Once completed, we then started to record and analyze our cutting results from both a physical standpoint (even cuts) and an operational performance standpoint (number of cuts per blade). After a full day of cutting, we gathered the pertinent data, and then began our preparation for a presentation on our overall results to both George and Mike.

On the 2nd day, we put on the WIKUS FUTURA® SN and programed the saw to our preferred, operational settings (feeds and speeds). At the beginning, we first conducted our standard break-in cut to allow the tooth pattern to smooth out and enhance the removal rates. Once completed, we then started to record and analyze our cutting results from both a physical standpoint (even cuts) and an operational performance standpoint (number of cuts per blade). After a full day of cutting, we gathered the pertinent data, and then began our preparation for a presentation on our overall results to both George and Mike.

At the meeting, we were clearly able to show how we performed based on Rockland’s specific needs, versus their current supplier, in terms of both data performance and physical appearance. The visual performance easily out-performed the incumbent, which was actually a real win for Rockland, as this reduced a great amount of re-work down-stream, which was caused by the consistent, uneven cuts they were achieving before.

At the meeting, we were clearly able to show how we performed based on Rockland’s specific needs, versus their current supplier, in terms of both data performance and physical appearance. The visual performance easily out-performed the incumbent, which was actually a real win for Rockland, as this reduced a great amount of re-work down-stream, which was caused by the consistent, uneven cuts they were achieving before.

W hen we analyzed the number of cuts per blade, the WIKUS FUTURA SN made 182 cuts versus the 109 cuts from the incumbent’s blade. This resulted in a net productivity increase of 67% more cuts per blade with the WIKUS FUTURA SN blade versus the incumbent. Not only did we improve productivity and the physical performance of the material, but we also decreased the amount of time to make a cut, by a minimum of 30% per cut.

hen we analyzed the number of cuts per blade, the WIKUS FUTURA SN made 182 cuts versus the 109 cuts from the incumbent’s blade. This resulted in a net productivity increase of 67% more cuts per blade with the WIKUS FUTURA SN blade versus the incumbent. Not only did we improve productivity and the physical performance of the material, but we also decreased the amount of time to make a cut, by a minimum of 30% per cut.

Upon reviewing these specific performance results, the team at Rockland decided to immediately purchase 20 blades through our distribution partner, Hercules Sealing Products. In working with both Rockland and WIKUS, Hercules has committed to carrying the required inventory necessary to properly service and exceed Rockland’s production demands in the future.

So, after 6 months, this opportunity really gave me a true understanding of the product quality and technical expertise that WIKUS possesses as an organization. It also clearly showed me that by focusing on the true issues of the customer, solving the true problem is far more valuable to a customer, than just providing a low-price, cheaper saw blade. This story is just a small example of the many great successes that WIKUS can bring to your organization. So, if you are looking to improve your sawing operations and your overall productivity, please contact your local WIKUS Saw Technology Regional Sales Manager for more details.