Band sawing techniques for titanium are no more difficult than those for other high performance metals; for instance the austenitic stainless steels. Reasonable production rates and excellent surface finish are readily attainable on sawed parts, provided some unique characteristics of titanium are taken into account. These characteristics are:

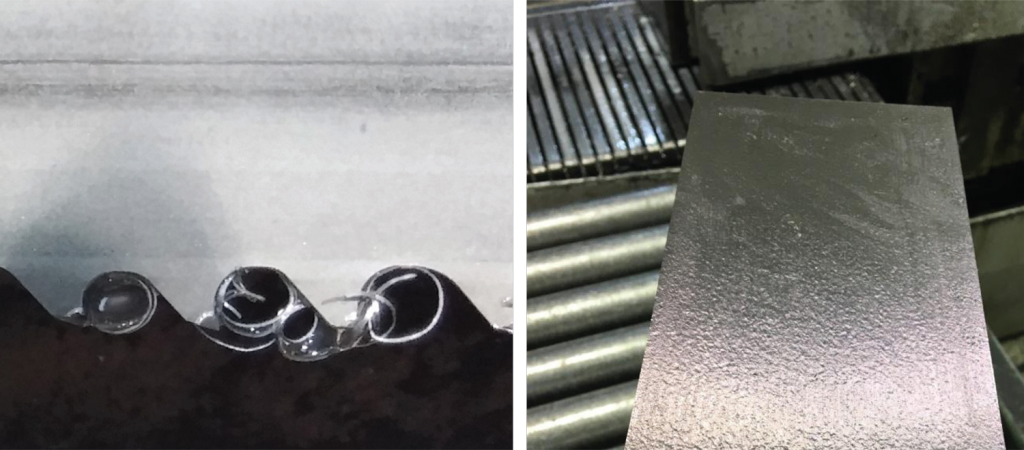

- The unusual chip-forming tendency and low thermal conductivity of titanium tends to cause a build-up of heat on the edge and face of cutting tools.

- The reactivity of titanium with cutting tools contributes to seizing, galling, abrasion and pick up on cutting edges and faces.

- The low elastic modulus of titanium permits greater deflections of work pieces and, therefore, may require proper backup.

Machining conditions can be selected which minimize or circumvent the adverse effects of these characteristics of titanium, thereby allowing good tool life at acceptable production rates.

Observation of the following seven guidelines will aid in successfully machining titanium:

- USE LOW CUTTING SPEEDS

Tool tip temperature is strongly affected by cutting speed. A low cutting speed helps to minimize tool edge temperature and maximize tool life. Lower speeds are required for titanium alloys such as Ti-6Al-4V than for unalloyed titanium. - MAINTAIN HIGH FEED RATES AND CONSISTENT DECENT RATES

Tool temperature is affected less by feed rate than by speed. Therefore, the highest rate of feed consistent with good practice should be used. The depth of cut should be greater than the work hardened layer resulting from the previous cut. - USE A GENEROUS QUANTITY OF CUTTING FLUID

The coolant carries away heat in addition to washing away chips and reducing cutting forces, thereby improving tool life. - MAINTAIN SHARP TOOLS

Tool wear results in build-up of metal on cutting edges and causes poor surface finish, tearing and deflection of the work piece. - NEVER STOP FEEDING WHILE TOOL AND WORK ARE IN MOVING CONTACT

Permitting a blade to dwell in moving contact with titanium causes work hardening and promotes smearing, galling and seizing, which may lead to total tool breakdown. - USE RIGID SETUPS

Rigidity of the blade (proper blade tension) and work piece (secure clamping) ensures a controlled depth of cut and reduced vibration - USE WIKUS PARAMASTER

For best cutting recommendations on the various grades and conditions of the material being cut.

A Few Titanium and Titanium Alloys

Material # DIN #

3.7025 Ti 1

3.7124 TiCu2

3.7195 TiAl3V2.5

3.7225 Ti1Pd

3.7115 TiAl5Sn2

3.7145 TiAl6Sn2Zr4Mo2Si

3.7165 TiAl6V4

3.7175 TiAl6V6Sn2

3.7185 TiAl4Mo4Sn2