This recent success story illustrates the triangular relationship between the end-user, distributor and Wikus.

This recent success story illustrates the triangular relationship between the end-user, distributor and Wikus.

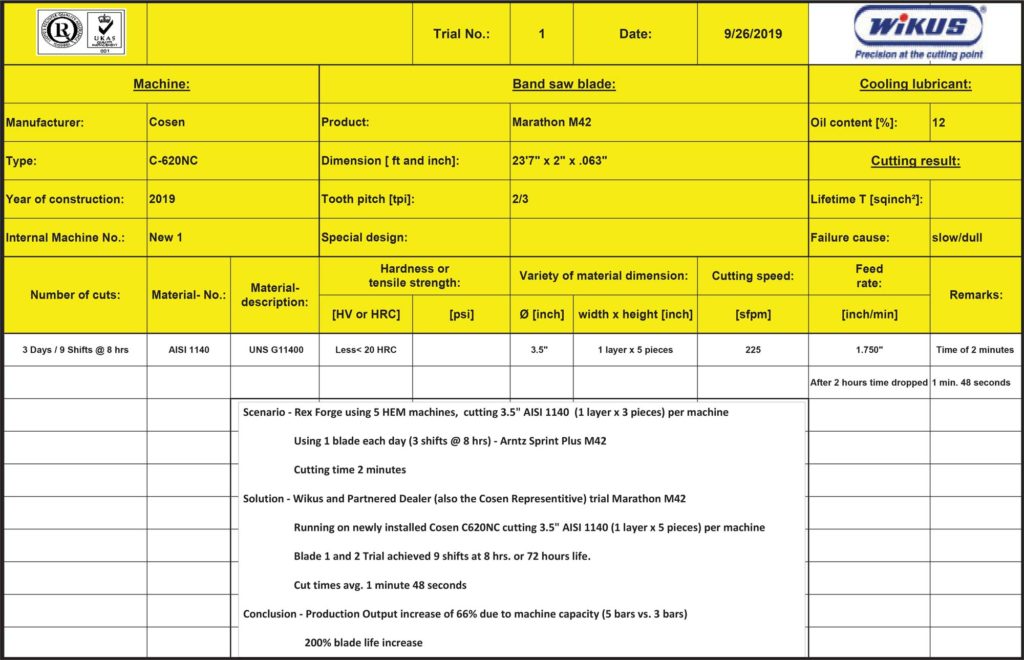

In this sawing application the forge producing customer had been operating 5 machines; each with the capacity to cut 3 pieces per cut with a 2- minute cut time and operating 3 (8hr) shifts per day for 6 days a week. The machines were in tough shape and had earned their keep over the years where they typically processed over 70 million pounds of SBQ Steel (Special Bar Quality) annually to forge drive-train components for medium and heavy-duty trucks.

Wikus was given the opportunity to test blades with a partnered distributor who had recently installed a new saw which gave the capacity to cut 5 pieces per cut. The objective was to maintain the same 2- minute cut time and increase their current blade life of 1 blade per 3 shifts (24hrs).

Our selection for cutting the 3.5″ diameter AISI 1140 material was the tried and true MARATHON ® M42 – The all-purpose Level 2 blade for medium and large cross-sections.

Our selection for cutting the 3.5″ diameter AISI 1140 material was the tried and true MARATHON ® M42 – The all-purpose Level 2 blade for medium and large cross-sections.

After a short break-in of the blade, we were able to maintain the 2-minute cut time requirements and extend the blade life to 9 shifts (72hrs).

The additional machine holding capacity increased piece output by 66% and we were able to increase the current blade life 200%. The substantial increase in blade life could potentially reduce consumption of blades to 1/3 their current usage. Working hand in hand with the end-user and our distributor gave us the ability to combine all efforts in bringing a successful solution one cut at a time. Please let us know if you have any stories you would like to share with our readers.