Overcoming Difficult Cutting Challenges in Machining

In machining operations, cutting challenges arise from a variety of factors, including material hardness, tool wear, heat generation, and precision requirements. Addressing these challenges effectively requires a combination of advanced cutting techniques, optimized tooling solutions, and data-driven machining strategies. Understanding these complexities and implementing best practices can lead to improved efficiency, reduced waste, and enhanced component quality.

Understanding the Complexity of Cutting Difficult Materials

Machining difficult-to-cut materials such as hardened steels, superalloys, and composite materials presents unique challenges. These materials often exhibit high heat resistance, extreme hardness, and abrasive properties, leading to increased tool wear and reduced cutting efficiency.

For instance, aerospace components often require machining of titanium and Inconel, which generate significant heat and wear down cutting tools quickly. The medical industry frequently deals with stainless steel and cobalt-chrome alloys, requiring high precision and surface integrity. To overcome these challenges, machinists must carefully select cutting parameters, tooling materials, and cooling strategies.

Tooling Considerations for Difficult Cuts

The right tooling selection is critical when dealing with tough cutting conditions. Carbide, ceramic, cubic boron nitride (CBN), and polycrystalline diamond (PCD) cutting tools offer superior wear resistance and longevity compared to conventional high-speed steel (HSS) tools.

Key tooling considerations include:

- Coatings and Tool Geometry: Coatings such as titanium aluminum nitride (TiAlN) or diamond-like carbon (DLC) enhance tool life by improving heat resistance and reducing friction. Optimized tool geometries, such as chip breakers and variable helix angles, can further improve cutting stability and chip evacuation.

- Adaptive Cutting Techniques: Using variable feed rates and step-over strategies can prevent excessive tool wear while maintaining precision in high-performance machining applications.

- Minimum Quantity Lubrication (MQL): This technique reduces coolant usage while improving lubrication and cooling efficiency, minimizing thermal damage to tools and workpieces.

Case Study: Managing Tool Wear in High-Performance Machining

A manufacturer of automotive components faced significant tool wear issues when machining hardened steel drive shafts. The high hardness of the material caused rapid degradation of traditional carbide inserts, leading to frequent tool changes and increased downtime.

By switching to CBN cutting tools with optimized edge preparation and advanced coatings, the company achieved a 60% increase in tool life. Additionally, implementing a dynamic cutting strategy with real-time monitoring helped fine-tune spindle speeds and feed rates, reducing heat buildup and improving tool performance.

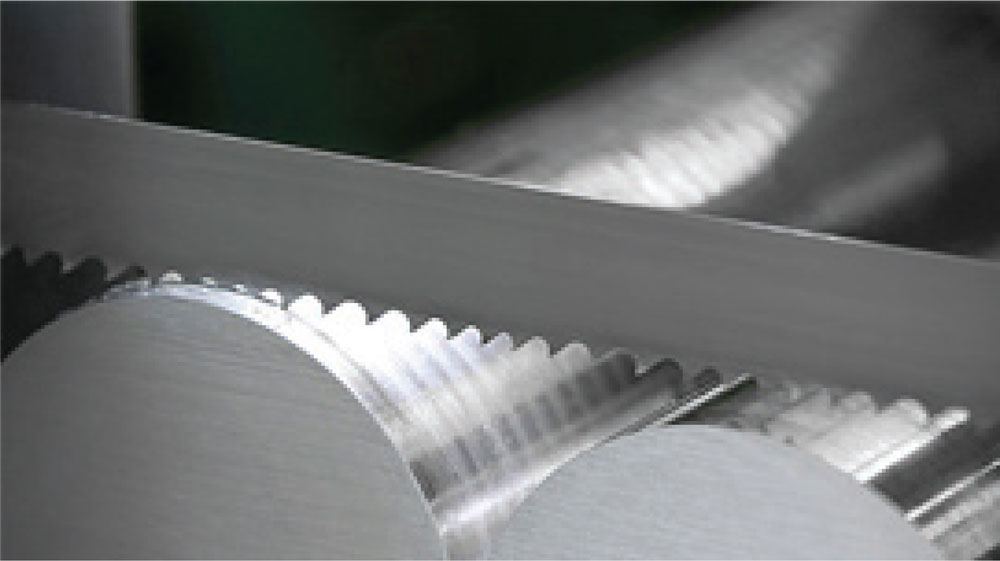

Companies like WIKUS, which specialize in high-performance saw blades, have also developed advanced solutions to address cutting challenges. Their focus on material efficiency and blade longevity helps manufacturers improve cutting performance while minimizing waste.

Optimizing Cutting Parameters for Improved Performance

Fine-tuning cutting parameters can make a significant difference in tackling difficult machining challenges. Adjusting factors such as cutting speed, feed rate, depth of cut, and chip load ensures optimal tool engagement and material removal efficiency.

Key Strategies:

- Reduced Cutting Forces: Lowering feed rates and increasing spindle speed can help reduce excessive cutting forces that lead to tool breakage.

- High-Speed Machining (HSM): Implementing high-speed machining techniques with small radial depth cuts can enhance surface finish and reduce heat buildup.

- Predictive Tool Wear Monitoring: Using advanced monitoring systems, such as vibration analysis and infrared thermography, can help predict tool wear before it leads to costly failures.

Leveraging Smart Machining and Automation

The integration of Industry 4.0 technologies into machining operations has transformed the way difficult cutting challenges are managed. Smart machining solutions, including real-time data collection, AI-driven predictive maintenance, and robotic automation, contribute to more efficient and reliable machining processes.

Applications of Smart Machining:

- Real-Time Adaptive Control: Automated adjustments to machining parameters based on cutting conditions ensure consistency and prevent tool damage.

- Machine Learning for Process Optimization: AI algorithms analyze past machining data to suggest optimal tool paths and cutting conditions.

- Robotic Tool Handling: Automated tool changers and robotic-assisted machining improve efficiency in high-precision manufacturing environments.

Conclusion

Tackling difficult cutting challenges in machining requires a multi-faceted approach that includes selecting the right tooling, optimizing cutting parameters, and integrating smart manufacturing technologies. By leveraging advanced materials, coatings, and process optimization techniques, manufacturers can improve efficiency, extend tool life, and enhance product quality. Companies like WIKUS demonstrate how innovative cutting solutions can contribute to overcoming machining challenges while supporting sustainable and efficient manufacturing practices. As the machining industry continues to evolve, staying ahead of cutting challenges will be essential for maintaining competitiveness and operational success.