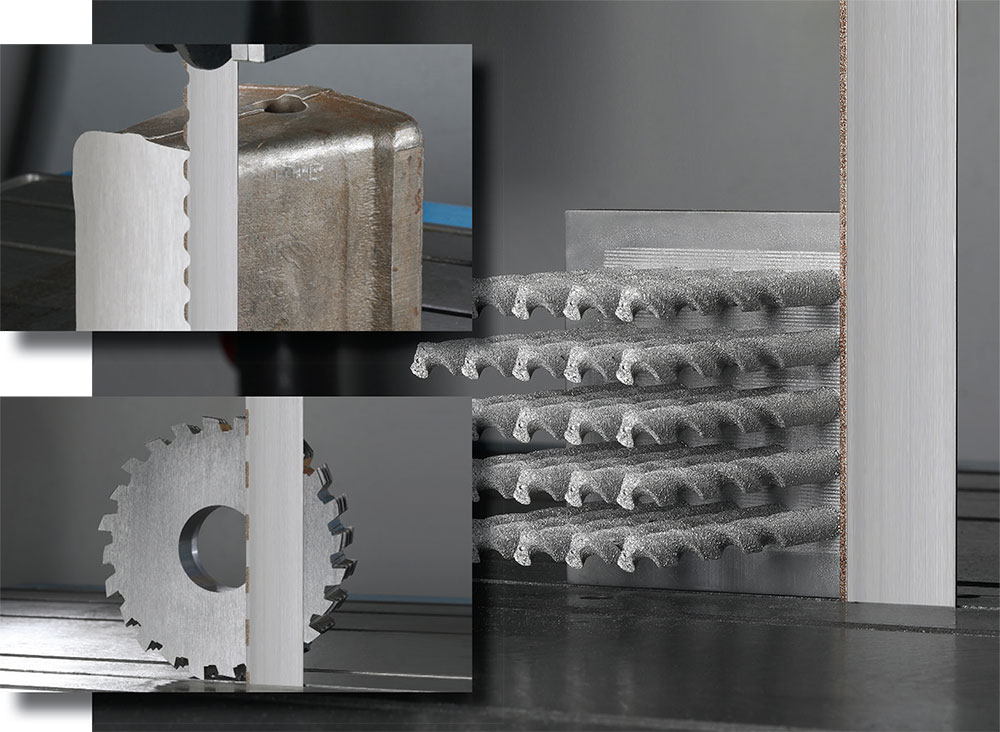

WIKUS has added to its range of band saw blades with cubic boron nitride (CBN) coated saw bands CUBOGRIT®. Cubic boron nitride is the second hardest known material, whose properties include not only high hardness and strength but also thermal and chemical resistance. These properties make CUBOGRIT® saw blades ideal for the reliable machining of hardened ferrous and hard alloys as well as for 3D-printed hard alloys. With CUBOGRIT®, even the hardest alloys of up to 70 HRC can now be sawn economically. The machineside conditions of a cutting speed reaching at least 3,900 surface feet per minute must be fulfilled.

APPLICATION

• Hardened ferrous materials up to 70 HRC

• Hard alloys

• 3D-printed hard alloys

• hardened high-speed steel (HSS), casehardened steels

• high-alloyed tool steels up to 55 HRC

• iron-based powder coatings, chilled castv iron, stellite

• small workpiece dimensions

PROPERTIES

• very low wear with suitable application

• very high thermal conductivity

• chemical resistance

• hardness of CBN unchanged even at temperatures up to 1000° C

• optimum backing material for use at extremely high cutting speeds

• grain sizes of B91-B601 **depending on the application and dimension available**

• complete CBN assignment at the cutting edge of the blade

• Backing strip made of alloyed tempered steel

ADVANTAGES

• no chipping at the contour edges

• low post-processing due to very good surface finish

CUBOGRIT® K is also available with backing made of corrosion-resistant special steel as CUBOGRIT® K VA. This version offers the following advantages:

• cooling with pure water

• no corrosion of the backing during longer downtimes