When we call on a prospective blade user, one of the keys to making the right blade recommendation is to compare the current data being collected and know what solution you are trying to deliver. What are you trying to achieve? Cut at a higher removal rate, give longer blade-life, or improve the surface finish? Maybe it’s a combination of all 3. Based on the observations you make and the information you record, your chances for success will increase dramatically. The goal is delivering the lowest cost per cut while meeting your customer’s requirements.

To meet or improve the current performance you must offer the product that is best suited for their application. If you ask all the right questions, you can deliver several options from our various levels of product offerings.

- What materials are being cut – type, dimensions, frequency (80% vs. 20%)

- What size is the material – square, rectangle, round?

- What machine Make and Model

- What is the current blade in use – brand, specific name, features (edge type, ground tooth, heavy set)

- Current tooth pitch selection – constant pitch, variable pitch, zero rake, positive rake

- Speed of blade – observe and record what speed is currently used on the application, note what speeds are available on the machine (variable, step pulley, fixed)

- Feed setting – observe and record the current down feed setting (psi, numerals, slide weight)

- Cut time – observe and record the current time required to make the cut

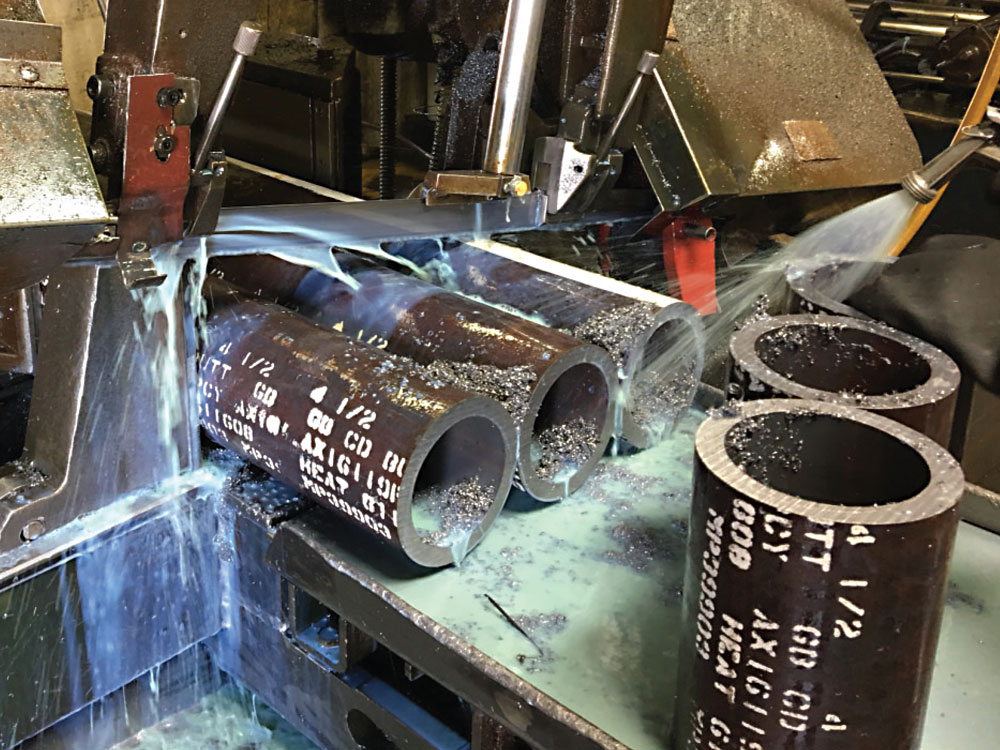

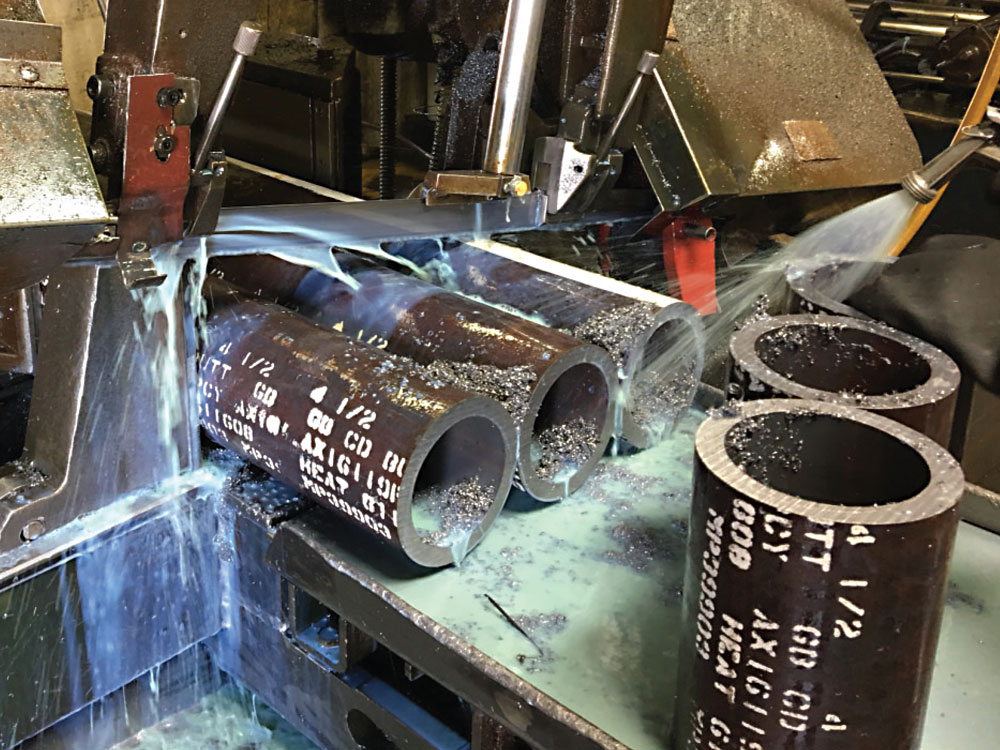

- Coolant – observe coolant flow and ratio

- Chips – observe chips (discolored, stringy, tight)

- Surface finish – observe finished surface condition for roughness and burr

Once you determine your product and before you start cutting,

check the following to ensure proper adjustments are made.

- Adequate blade tension

- Guide support of blade

- Guide arm distance to work piece

- Chip removal brush adjusted properly

- Coolant flow and ratio

- Head decent rate (based on sq” removal)

- Ensure complete through cut

- Adequate vise clamping

- Blade alignment (squareness to bed and vise)

- Blade speed set for material type and size

- Cutting rate established for material type

- Break in blade

Remember, if we ask all the right questions we can deliver the

best solution.