Cost optimization and resource conservation are the factors of success for efficient production processes. Our product program has a WIKUS band saw blade solution for almost every application – from Low Carbon steels to the high Nickel/Chrome Alloys, titanium alloys, composite materials, concrete, rubber, silicon. The list goes on and on. No matter what it is that you’re cutting, we’ll help you select and use our high-performance blades that are matched to your individual needs.

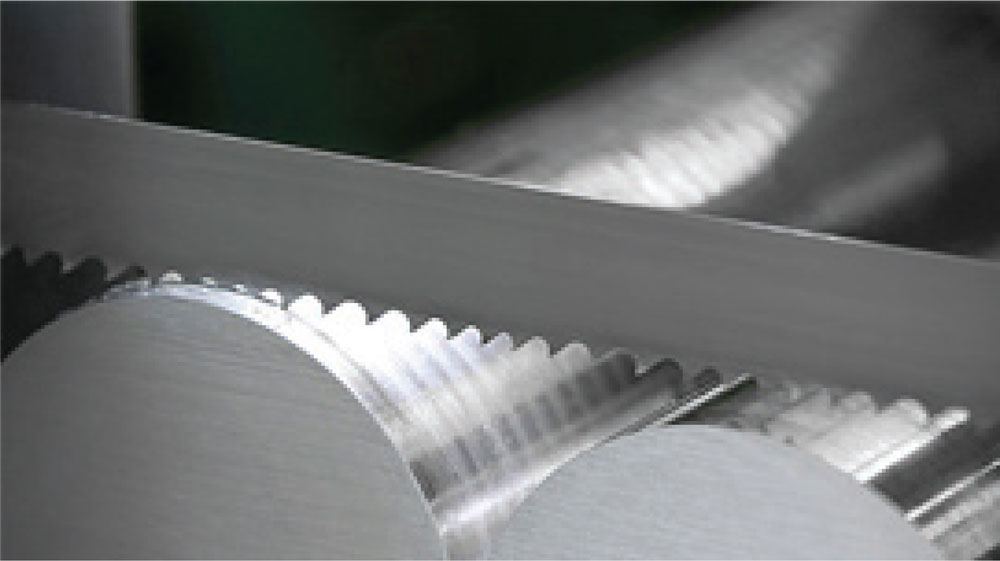

Application fields for bimetal band saw blades

Cutting edge- M42:

- Construction, deep-drawn and machining steels

- Case-hardening steels, spring steels and ball-bearing steels

- Non-alloyed tool steels

- Cast iron

- Nitrided and high-speed steels

- Rust and acid-resistant steels (easy to machine)

- Non-ferrous metals (aluminum, copper, brass)

- Low and high-alloy tool steels for hot work

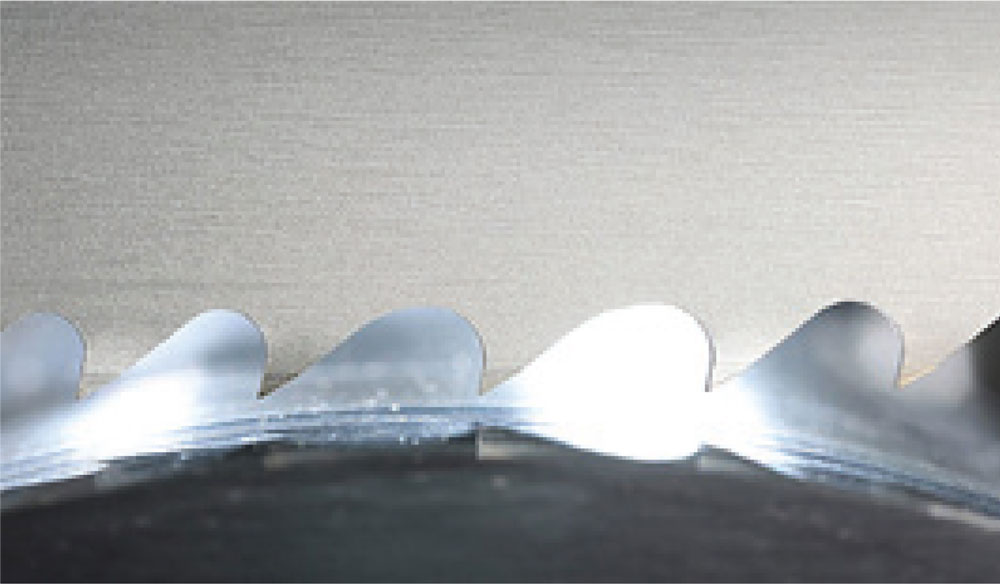

Cutting edge- X3000:

- High-alloy tool steels for cold work

- Rust and acid-resistant steels (difficult to machine)

- Heat-resistant, high temperature-resistant and duplex steels

- Aluminum bronzes

- Nickel-based alloys

- Titanium alloys

- Steels with a tensile strength Rm of 1000-1300 N/mm²