Cap Coupes Services handles customer-specific cuts for a variety of materials. The French supplier is cooperating with WIKUS to optimize its cutting processes.

The demands that Cap Coupes Services places on band saw blades are high: due to the large number of different materials and cross-sections to be cut – such as titanium, Inconel or super-duplex steel – the company needed numerous tools for various applications as well as reliable high-performance band saw blades. To optimally meet these high demands, the company looked for a full service partner with a comprehensive product range, extensive technical know-how and many years of consulting expertise in efficiency.

The WIKUS team impressed Cap Coupes Service immediately due to its extensive knowledge in the field of band saw blades and other cutting tools, its wide range of high-tech products and excellent results in the initial cutting tests. These were followed by more in-depth field tests under realistic application conditions, including a thorough analysis of the cutting costs in which the customer attached great importance to the quality and efficiency of the products. Due to the know-how and expertise, WIKUS was named the new main supplier for all of the cutting service provider’s sawing applications.

Durable band saw blades

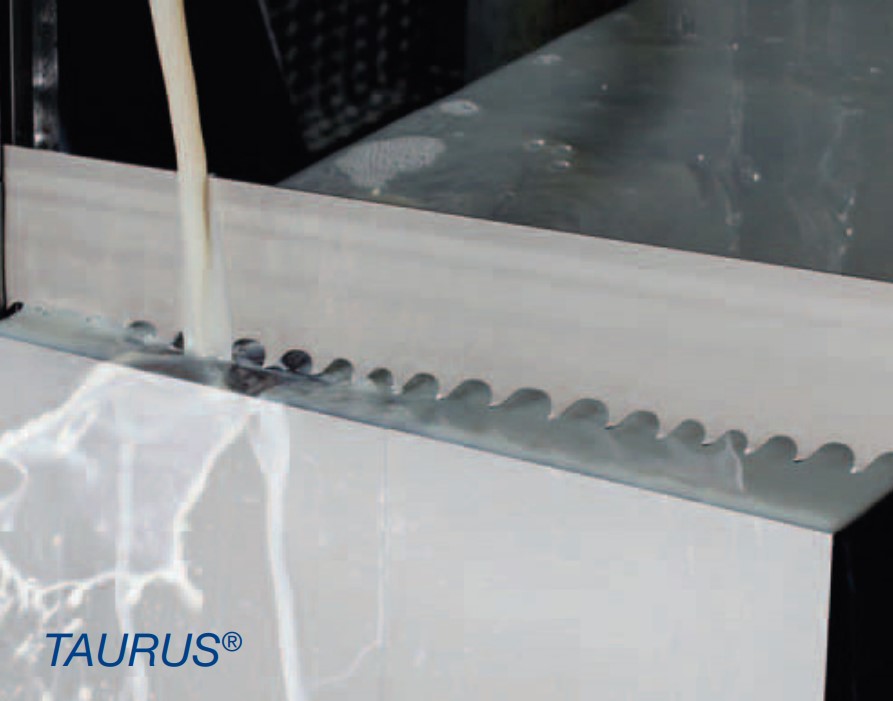

Based on the tests, Cap Coupes Services selected the products TAURUS® and SKALAR® PREMIUM M42 as well as a custom-made product. TAURUS® is an inexpensive carbide tipped band saw blade for basic applications. It is suitable for solid materials, including all steels and non-ferrous metals, and can also be used on machines without a carbide package. The good surface quality ensures that minor reworking is necessary.

Based on the tests, Cap Coupes Services selected the products TAURUS® and SKALAR® PREMIUM M42 as well as a custom-made product. TAURUS® is an inexpensive carbide tipped band saw blade for basic applications. It is suitable for solid materials, including all steels and non-ferrous metals, and can also be used on machines without a carbide package. The good surface quality ensures that minor reworking is necessary.

In comparison, SKALAR® PREMIUM M42 ensures a high performance and an extra-long blade-life. The band saw blade can be used for all metals with a tensile strength of up to 1000 N/mm². With its high cutting performance, it is also suitable for continuous operation in large sawmills. The tooth edge has a special coating which – combined with a back edge coating – reduces friction. The user benefits from a vibration-resistant smooth running that results in long blade life.

As part of the collaboration, a customized band saw blade was also developed, with a special tooth pitch for a band width of 2 5/8” (67 mm) for specific applications. The decisive variables for the selection of the tooth pitch were the contact length of the band saw blade in the work piece and the material that is to be cut.

In order to provide the French metal cutting specialist with the best possible support regarding the selection of the right cutting solutions for its specific requirements, WIKUS assisted it with comprehensive consultation and testing on site. This included training sessions which introduced the new band saw blades and familiarized the employees with the correct handling. This service ensures that the blades achieve optimum cutting results, and thus contribute to significant cost savings.

In addition, significant improvements were made thanks to the ParaMaster® online tool, which simplifies and speeds up the analysis and optimization of cutting processes for the customer. The program allows the user to view one concrete recommendation and several additional recommendations for WIKUS band saw blades quickly, simply and free of charge, including the appropriate cutting parameters for the customer-specific application scenario. If the user enters additional variables, such as the production cost, hourly rates and the blade-life of the band saw blades, he will get particularly realistic cutting costs and can reduce these further by optimizing the parameters.

In addition, significant improvements were made thanks to the ParaMaster® online tool, which simplifies and speeds up the analysis and optimization of cutting processes for the customer. The program allows the user to view one concrete recommendation and several additional recommendations for WIKUS band saw blades quickly, simply and free of charge, including the appropriate cutting parameters for the customer-specific application scenario. If the user enters additional variables, such as the production cost, hourly rates and the blade-life of the band saw blades, he will get particularly realistic cutting costs and can reduce these further by optimizing the parameters.

More than 50 % growth

“We have very sophisticated customers with high requirements in terms of time, cost, quality and tolerance,” says Daniel Caprio, President of Cap Coupes Services. “WIKUS provides us with efficient and effective support. The company’s various and powerful band saw blades help us to maintain a high level of productivity and short delivery periods. The very competent technical and personal support and the use of the pioneering ParaMaster® software, which we use to optimize our cutting parameters, were crucial for the success of our operation. In summary, WIKUS has been instrumental in helping our business grow by more than 50% over the last five to eight years.”