Whether you’re creating continuous chips, serrated chips, discontinous chips or chips with built up edge, pulling a consistent chip load is the key to success. Chips come in various shapes, sizes and colors and each can indicate what machine adjustments might be needed to create the desired chip.

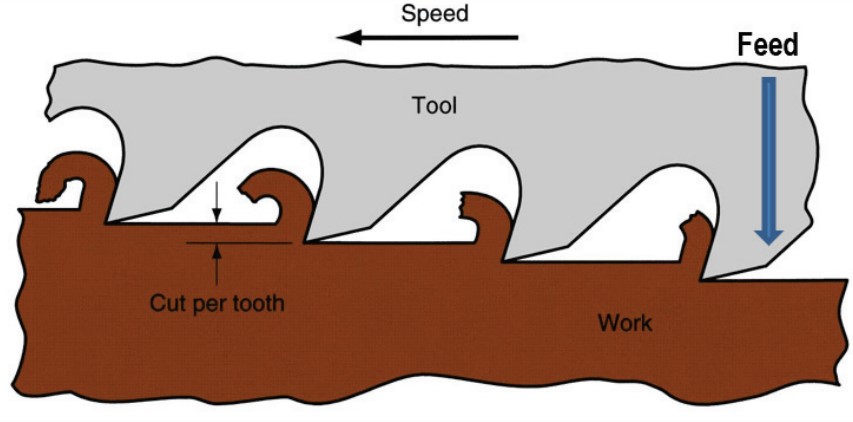

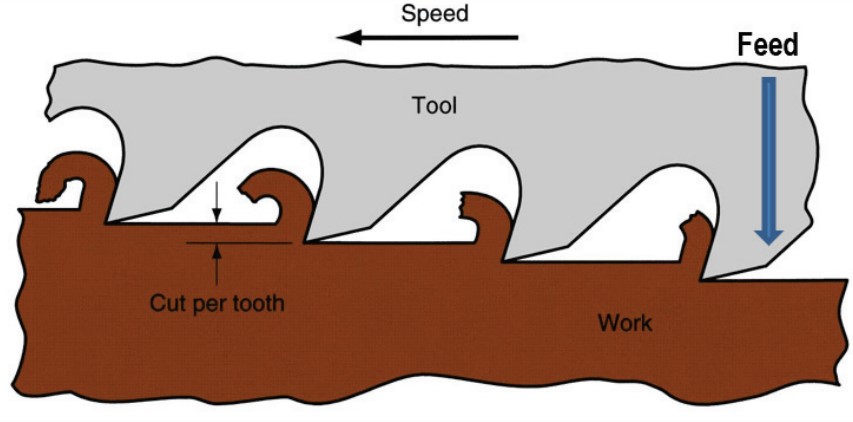

Chip Load is the amount of material each tooth removes as it passes through the workpiece. Too thin a chip causes the cutting edge to rub, creating excessive heat at the tooth tip dulling the cutting edge. Too thick a chip will overstress the tooth tip causing it to chip and wear prematurely. Maintaining a consistent chip load is key to:

Chip Load is the amount of material each tooth removes as it passes through the workpiece. Too thin a chip causes the cutting edge to rub, creating excessive heat at the tooth tip dulling the cutting edge. Too thick a chip will overstress the tooth tip causing it to chip and wear prematurely. Maintaining a consistent chip load is key to:

- Controlling the required force to cut the material

- Controlling heat at the tip

- Controlling tool wear along the cutting edge

- Controlling the removal rate in square inches per minute

- Controlling surface finish

- Controlling cut deflection and deviation

Feed Rates and Speeds are very important topics when it comes to cutting metals and achieving performance and tool life. Both have a very important role in creating and maintaining a consistent chip load throughout the cut working together to accomplish this.

Speed is the motion of the blade measured in surface feet per minute (sfpm). Based on material type, dimension and condition, blade speed will vary in recommendation.

Feed Rate refers to the movement of the blade into the work piece, is generally measured in inches per minute (ipm) and is established to achieve a given square inch per minute removal rate for that material type and size being cut based on its machineability.

A simple formula to calculate your feed rate would be to take the recommended square inch removal rate for your material and divide it by the cross section to be cut. Example: recommended removal rate of 2 square inches per minute cutting a 4” cross section of 316 Stainless Steel (2 divided by 4 = .500) Feed Rate of .500” per minute.

A simple formula to calculate your feed rate would be to take the recommended square inch removal rate for your material and divide it by the cross section to be cut. Example: recommended removal rate of 2 square inches per minute cutting a 4” cross section of 316 Stainless Steel (2 divided by 4 = .500) Feed Rate of .500” per minute.

When the correct feed and speed ratios are used the chip load becomes uniform and consistent, thus resulting in performance and longevity of the blade.